Jako producent krat z TWS zapewniamy najwyższą jakoś naszych produktów. Kraty z tworzywa sztucznego, wzbogacone o włókno szklane TWS. Wyróżniają się niską wagą oraz niezwykłą wytrzymałością na uszkodzenia mechaniczne i niekorzystne warunki zewnętrzne.

W Trokotex oferujemy kraty z tworzywa, które są nierdzewne, kwasoodporne, antypoślizgowe wykonane z wysokiej jakości włókna szklanego i żywicy.

Zastosowanie naszych krat: Pomosty robocze; Stopnie schodów; Podłogi; Platformy; Pokrycia kanałów; Pokrycia studzienek i Odstojników.

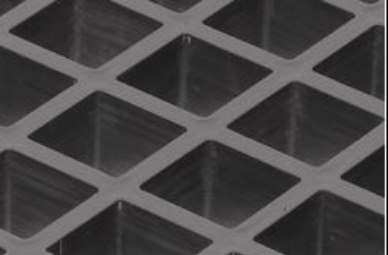

Kraty pomostowe wytwarzane są z tworzywa wzmocnionego włóknem szklanym (TWS) ineczej zwany kompozytem, wysokogatunkowych żywic syntetycznych i włókien szklanych. W pierwszej fazie produkcji ciągłe pasma włókna szklanego (rowing) naciągane są na urządzeniach formujących, a następnie włókna przesycane są żywicami syntetycznymi i poddawane utwardzeniu. Krata jest zbrojona w identyczny sposób w kierunku wzdłużnym i poprzecznym, dzięki czemu charakteryzuje się jednakową wytrzymałością w każdym kierunku, a dowolne krawędzie kraty mogą służyć jako elementy nośne.

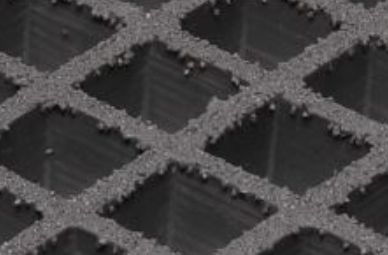

W zależności od typu zastosowanej żywicy do przesycenia włókna szklanego otrzymujemy laminat: chemoodporny standardowy (na bazie żywicy poliestrowej); o podwyższonej chemoodporności (na bazie żywicy winyloestrowej); trudno zapalny wg PN-EN 13501-1:2007 i ITB 401/2014 (na bazie żywicy samogasnącej) Kraty pomostowe mogą zostać wykonane w wersji z powierzchnią gładką lub przeciwpoślizgową. W przypadku wyrobów z powierzchnią przeciwpoślizgową podczas wytwarzania na roboczej powierzchni zatapiane są cząsteczki krzemianu o średnicy 0,3-0,8mm.

Właściwości naszych krat pomostowych pozwalają na:

redukcję ciężaru konstrukcji redukcję kosztów ze względu na łatwość obróbki i możliwość stosowania w elementach docinanych i przewiercanych wytrzymałość w trudnych warunkach atmosferycznych i zwiększoną trwałość dzięki wysokiej odporności chemicznej i korozyjnej uproszczenie procesu budowlanego dzięki łatwości montażu

Zalety i korzyści

Ze względu na całkowicie zautomatyzowany system produkcji kraty pomostowe TROKOTEX z powodzeniem zastępują tradycyjne kraty STALOWE.

Jako producent krat z TWS zapewniamy najwyższą jakoś naszych produktów. Kraty z tworzywa sztucznego, wzbogacone o włókno szklane TWS. Wyróżniają się niską wagą oraz niezwykłą wytrzymałością na uszkodzenia mechaniczne i niekorzystne warunki zewnętrzne.

W Trokotex oferujemy kraty z tworzywa, które są nierdzewne, kwasoodporne, antypoślizgowe wykonane z wysokiej jakości włókna szklanego i żywicy.

CERTYFIKAT ISO 9001 i 14001

Antykorozyjność

Kraty pomostowe z kompozytu są całkowicie odporne na korozję co pozytywnie wpływa na ich długą żywotność. Ponadto nasze kraty nie wymagają po dłuższym czasie skrobania, piaskowania czy też malowania.

Lekkość

Dzięki znacznie niższej wadze od stali pozwalają na łatwy i szybki montaż bez konieczności użycia ciężkiego sprzętu do podnoszenia. Nasze kraty to tylko 11,4 kg na metr kwadratowy (25mm wysokości) oraz 18,7 kg na metr kwadratowy (38mm wysokości).

Wytrzymałość

Wytrzymałość w trudnych warunkach atmosferycznych i zwiększoną trwałość dzięki wysokiej odporności chemicznej i korozyjnej.

Produkty

Kraty ażurowe niskie

z meniskiem wklęsłym

Kraty z tworzywa, które są nierdzewne, kwasoodporne, antypoślizgowe.

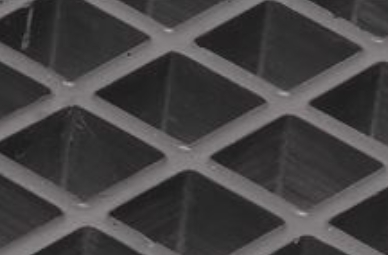

Kraty ażurowe wysokie

z meniskiem wklęsłym

Wyróżniają się niską wagą oraz niezwykłą wytrzymałością na uszkodzenia mechaniczne.

Akcesoria

Uchwyty montażowe występują w dwóch wariantach materiałowych: ze stali czarnej ocynkowanej ogniowo lub stali nierdzewnej. W zależności od środowiska pracy należy dobrać odpowiedni materiał uchwytów.

Wymiary i typy krat

Zastosowanie

Kraty pomostowe wykonane z tworzywa wzmocnionego szkłem (TWS) mają bardzo szerokie zastosowanie i doskonale sprawdzą się jako:

1. Pomosty robocze w instalacjach chemicznych, oczyszczalniach ścieków i przy wannach galwanicznych.

2. Pokrycia kanałów, studzienek i odstojników.

3. Ruszty w elektrolizerach, skruberach, filtrach i myjkach.

4. Stopnie schodów narażone na działanie płynów żrących.

5. Podłogi, platformy i inne w środowiskach silnego narażenie na korozję.

Sposoby mocowania

Kraty pomostowe RT dostarczane są przez producenta TROKOTEX w arkuszach o wymiarach standardowych. W razie Państwa zapotrzebowania kraty ażurowe można bez trudu przycinać na żądany wymiar elektronarzędziami z tarczą diamentową. Otwory na armaturę i przejścia rur przez kraty zaleca się wycinać na miejscu w trakcie montowania. Miejsca cięcia należy przemalować roztworem żywicy poliestrowej lub lakierem poliuretanowym.

Kraty pomostowe należy bezwzględnie mocować do konstrukcji nośnej za pomocą śrub oraz uchwytów mocujących zalecanych przez producenta, według niniejszych wytycznych. W przypadku, gdy kraty nie zostaną zamocowane skurcz technologiczny laminatu może spowodować odkształcenie się krat. Brak mocowania lub zastosowanie innych sposobów w montażu niż zalecane nie gwarantuje prawidłowej eksploatacji i zwalniają producenta z zobowiązań określonych gwarancją.

Zestawienie uchwytów mocujących kraty do konstrukcji nośnej, znajdą Państwo w zakładce akcesoria.

Podczas doboru sposobu montażu krat do konstrukcji nośnej należy kierować się wg następujących wytycznych:

Kraty o wysokości 25 mm:

– zalecane podparcie na wszystkich krawędziach (podparcie 2 krawędzi nośnych na całej długości, pozostałych co najmniej 20% długości centralnie w miejscu największego oddalenia od podpór),

– minimalna szerokość podparcia 40 mm,

– rozstaw podpór nie może być większy niż 1000 mm, w przypadku montażu arkuszy o większych wymiarach kratę należy dodatkowo podeprzeć w poprzek arkusza.

Kraty o wysokości 38 mm:

– zalecane podparcie na co najmniej 2 krawędziach,

– minimalna szerokość podparcia 40 mm,

– rozstaw podpór nie może być większy niż 1000 mm, w przypadku montażu arkuszy w większych wymiarach kratę należy dodatkowo podeprzeć w poprzek arkusza.

Tabela obciążeń

|

Typ kraty |

Rozstaw podpór, mm |

Obciążenie skupione, kg |

Obciążenie powierzchniowe, kg/m2 |

||

|---|---|---|---|---|---|

|

Ugięcie 1% |

Ugięcie 2% |

Ugięcie 1% |

Ugięcie 2% |

||

|

RT 40/25 |

500 |

263 |

530 |

1239 |

2488 |

|

600 |

219 |

442 |

947 |

1907 |

|

|

800 |

149 |

302 |

731 |

1476 |

|

|

1000 |

107 |

219 |

696 |

1405 |

|

|

RT 40/38 |

500 |

922 |

1869 |

2779 |

5613 |

|

600 |

723 |

1454 |

1332 |

4707 |

|

|

800 |

539 |

1086 |

1873 |

3773 |

|

|

1000 |

416 |

833 |

1687 |

3447 |

|

Zapytaj o ofertę

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod

Zadzwoń

+48 728 540 350

Napisz

kraty@en.trokotex.pl